For Production Control Lean Pull Systems Are Best Suited for

Semirepetitive batch manufacturing D. One of the concepts applied is called a pull system and in this article Steven Bonacorsi explains how to design one for your processDoing so will help you to stabilize a process flow into a predictable work control system.

Different Ways To Establish A Pull System Part 1 Allaboutlean Com

The pull production system is when the production is completely influenced by demand.

. Pull Systems work on the demand side such as Just-In-Time JIT or Continuous Replenishment Program CRP and keep inventory to a. Job shop production C. TF- Lean is an example of a pull system while lean thinking is an example of a push system.

Identify the environment best suited to lean manufacturing with an example. While pull systems work well in many cases for highly customized products or job shop environments pull systems are rarely the right solution. That is the batch and queue processes will replenish a supermarket of parts that would be consumed by a downstream one-piece flow process such as final.

A pull system is a lean manufacturing that promotes reduction of waste in production process. In a Pull System also known as Make to Order the production matches the customer demand or Takt time. None of the above.

None of the above. Asked Jul 26 2017 in Statistics by Yessica. Job shop production C.

Job shop production C. For production control lean pull systems are best suited for. Consider a job shop whose customers are ordering one-of-a-kind products in low volumes.

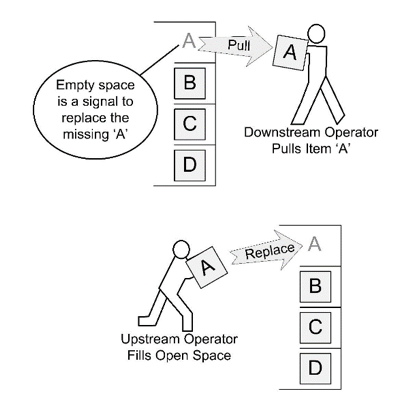

Long-term relationships and commitments. If a part leaves the system the kanban returns to the beginning of the loop and initiates reproduction. Semi-repetitive batch manufacturing D.

Semirepetitive batch manufacturing D. All of the above. Effectively the kanban is the signal.

For production control lean pull systems are best suited for. For production control lean pull systems are best suited for. The inventory is limited by the number of kanbans.

TF- According to the lean philosophy a stable master production schedule is desirable to reduce the work-in-process inventories. To create a uniform workload on all work centers. Job shop production C.

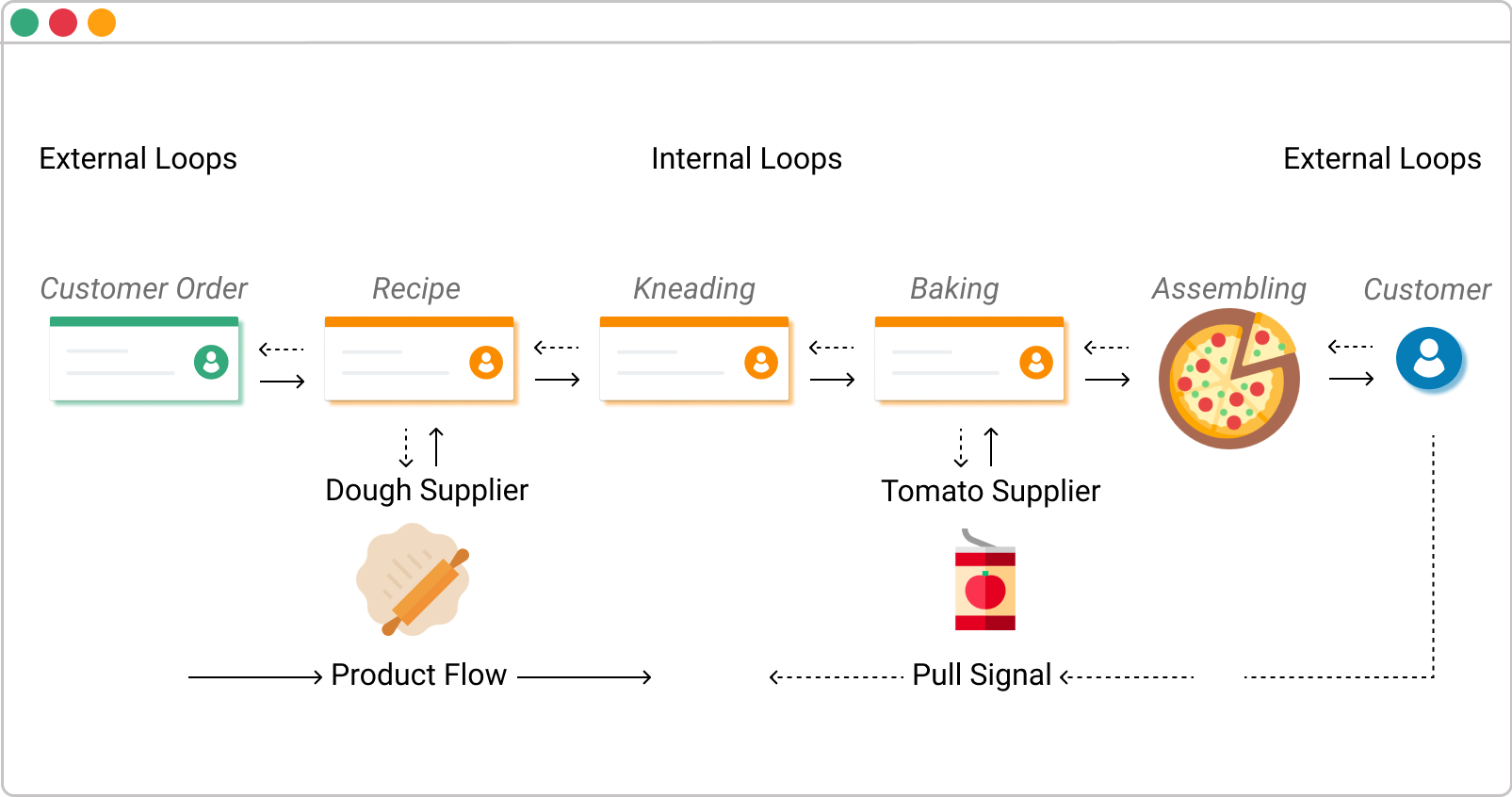

The pull production system and the push production system. Repetitive manufacturing is best suited. Pull production is not so easy to implement Toyota Company took 20 years to effectively implement the Pull production system.

Why is production leveled in a lean system. For production control lean pull systems are best suited for. For production control lean pull systems are best suited for.

Lean is an example of a pull system while lean thinking is an example of a push system. This blog post is loosely based on chapter 32 of my new book All About Pull Production. For production control lean pull systems are best suited for.

The service-profit chain shows that _____ is the key to profitability. This is one of the easiest ways to implement pull and there are even different. For production control lean pull systems are best suited for A.

None of the above A. Lets have a look. With regards to suppliers lean systems typically require.

When a certain product has demand it continues to be produced. For production control lean pull systems are best suited for. Lean Six Sigma is a leadership methodology that significantly improves process quality speed costs and agility.

Designing Implementing and Maintaining Kanban CONWIP and other Pull Systems in Lean Production. There is no doubt one of the hardest principles of Lean to implement as a manufacturer is the pull system. Asked Aug 23 2019 in Business by korn1990.

This is a cross post with the same article on. While the mass producer controls production using a traditional push system in which each manufacturing area is scheduled independently based on an MRP forecast the lean producer uses a pull system. For production control lean pull systems are best suited for.

In Traditional manufacturing products are processed in batches of materials from one work station WS to another and in each work station executed much work with several types of material flow because there are many jobs that. When you talk about Lean Production you can have two different types of production system. This is the best known way to establish pull production.

A pull system is not always the solution for production control within a lean producers value stream. Reducing setup time is important because it. In this post I finally give you a hands-on guide to decide which pull system to use.

Semi-repetitive batch manufacturing D. For production control lean pull systems are best suited for. When the demand starts to decrease the.

None of the above. With regards to suppliers lean systems typically require.

Pull Production Lean Enterprise Institute

Comments

Post a Comment